PARTICLE

An IDM Manufacturing Project

A decorative lamp inspired by the Möbius Strip.

50 units.

All hand-made @MIT.

Project Brief

Project time:

7 weeks

Project requirement:

Take a product from concept all the way through sales.

The product must be suitable as a holiday gift.

Production volume:

Minimum of 50 units, at least 25 units need to be sold in person at the Sales Gala.

Project Expenses:

Students are expected to cover the cost of prototyping and manufacturing investments.

Project success:

Projects are evaluated based on sell-through, profitability, creativity, and complexity.

Bottom line:

Design a holiday gift.

Make 50, sell 50.

When brainstorming 🧠, we wanted something that embodies the technical aspect of MIT but is also aesthetically pleasing and functional 👩🔧.

Evaluating our ideas

❣️ Desirability:

Is this something that someone would buy as a holiday gift? Is it going to be an impulse purchase? How do we market and brand the product? How can we demonstrate desirability?

🛠 Feasibility:

Can we make 50 units in the time frame that we have? What technical / manufacturing challenges do we foresee? What kind of quality can we expect? Can we get the material and the machine time we need in the timeframe that we have?

💰 Viability:

What is the financial viability of this? Will we be able to make a profit? How should we price our product? How much would our packaging and shipping cost be?

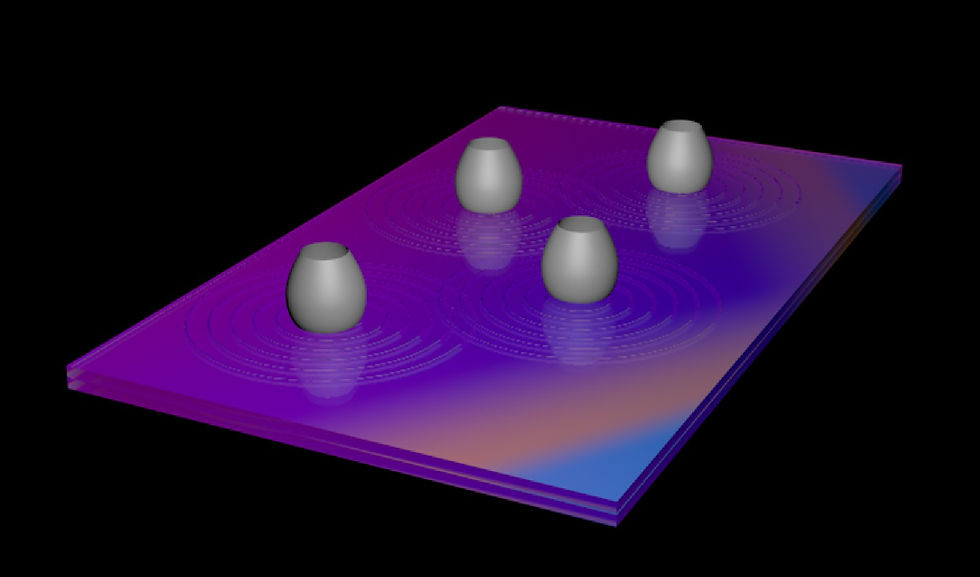

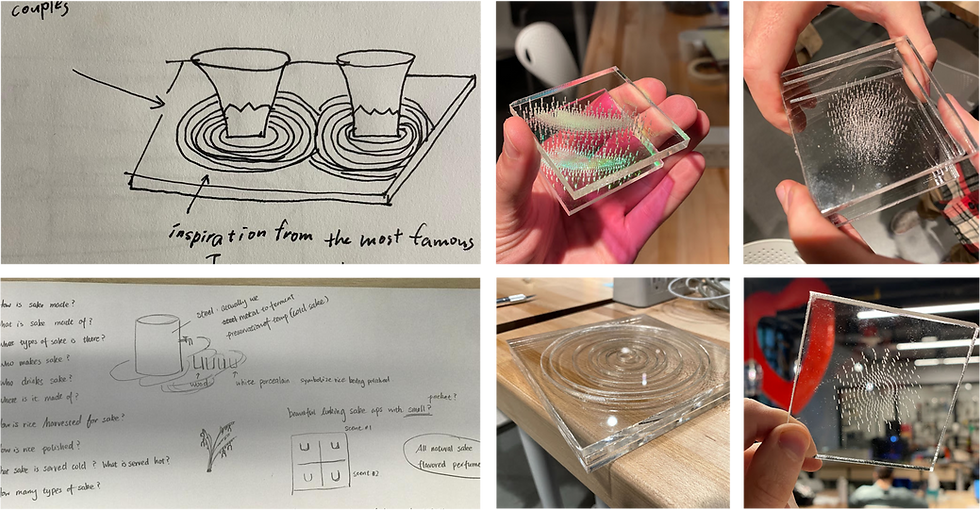

IDEA #1

a sake set that has optical illusionistic effects on the tray

So we prototyped a bunch:

💡 Eureka Moment #1 💡

We discovered that layering acrylic tiles that have etched dot patterns on them creates interesting 3D shapes.

3D Shape: The Möbius Strip

In searching for inspiration, we looked around campus and came across an article that described a piece of Robert Engman’s sculpture, which emulates a Möbius strip, that was previously suspended from the dome in the Barker Library, just under the Great Dome. It has since then been moved to the in Vassar Street Residence Hall in late 2020.

The Möbius strip is a one-sided surface that can be constructed by affixing the ends of a rectangular strip after first having given one of the ends a one-half twist. This space exhibits interesting properties, such as having only one side and remaining in one piece when split down the middle. It is the simplest non-orientable surface in euclidean space, a mathematical fascination.

Convert 3D shape into a dot matrix

We first modeled the Möbius strip in CAD, split the model into 10 sections, rasterized each section onto a plane, created the circular outlines based on the rasterization, then finally took the outlines and converted into a dot matrix based on the density.

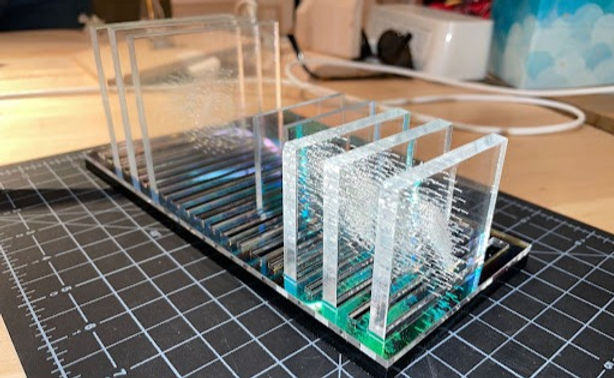

Meet Prototype #1 🤗

It's cool, but what is the product? How can we add functionality to it?

We modeled a list of things that we thought this could be turned into: a bookend, a coaster set, a parametric center piece, etc.

When in doubt, ask users!

And they said: what if it lights up?

Meet prototype #2

We were happy with this prototype and decided to move forward by making it into a decorative lamp 🛋

Next step:

DFM (Design for Manufacturing) 👷🏻🛠

1. Clean up design to achieve a sleek and minimalistic aesthetics

2. Think through assembly process and optimize mechanical and electronics design to simplify assembly and QC process, reduce error rate.

An example of our effort to optimize for DFM is the LED board design:

V0: we soldered cables to LED strips. This was time consuming and introduced a lot of error because it requires stripping 18 wires into tiny equal-length strips and would make the controller connection on the side.

V1: we considered using LED right angle connectors, but it would significantly increase the size of the base, therefore increasing our material cost and also making the base less aesthetically pleasing.

V2: we eventually came up with the idea to use copper tape on the side and solder the LED strip to the copper tape, which reduced the number of wires that we need to use and also made our assembly process a lot easier and less prone to error.

As we iterate the design for manufacturing, we also tested out the product with people to get feedback. And one feedback we got was that people were concerned about not being able to put the tiles back into the right slot to get the 3D effect. To solve this, we nerd-ed out a bit and added a binary coding to each tile so that every tile is unique and only fits into one slot.

In parallel to DFM, we put together our BOM (bill of Material) and kicked off sourcing.

Particle Hardware Components

Product dimensions

BOM & Sourcing

Step 1: Layout product dimensions and calculate the total amount of materials needed.

Step 2: Calculate material buffer.

Step 3: Get quote from 3 -5 suppliers for material cost, any additional cost for pre-processing materials, lead time, and shipping time.

Step 4: Calculate the most time and cost efficient supplier and place order.

Product Strategy

Strategy #1 Make the tiles removable so that customers can buy other patterns than the Möbius Strip. This has the potential to become a tile subscription model.

Strategy #2 Have different base acrylic top (mirrored & iridescent) to provide more aesthetic choices while maintaining the same manufacturing process and cost.

🛠 Manufacturing 🛠

Step #1: Finalize manufacturing process and prepping files

Step #2: Practice and training for all team members so that everyone can work on everything

Step #3: Lockdown machine time

Step #4: Plan work streams and hourly assembly shift

👆 Prepping files for laser cutting and etching

👆 Manufacturing process in stages. Click to view details

👆 Manufacturing in progress!

👆 In summary

All these efforts, how did we do in terms of financials? 💸

You can find our spending and our sales and profitability linked.

Where did we sell our products?

Sales Gala & Our Shopify store (particle.lighting)

Final Product Showcase

The Team

Daniel Jacobs Luengo

Katie Chen

Masumi Ito

Zach Sternberg

My role primarily involves engineering, manufacturing, and project management.